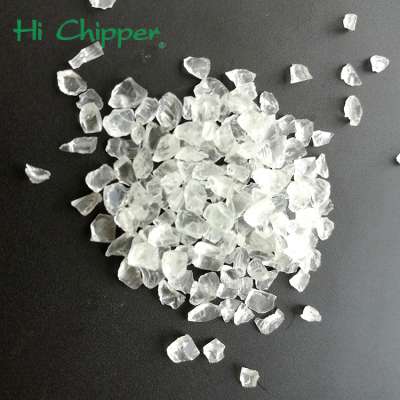

1.Efficiently cleans steel, aluminum, wood, concrete, stone, fiberglass

2.Excellent replacement to silica sand

3.Excellent for use as a separator or barrier with concrete pavers and forms. A layer of 2040 crushed glass prevents concrete forms from sticking to each other during the curing process and can be swept into the grout cracks during installation.

4.Glass blast will leave a clean, bright finish to metal surfaces

5.Excellent for achieving an aggressive profile for coatings, including cathodic protection and overlay performance

6.Glass delivers very low particle embedment (less than 2%) which produces a whiter (sp-10) finish to the substrate.

7.Lighter weight than most abrasives. Contractors report back that they use at least 25% less abrasive (some say up to 50% less) when using glass as compared to mineral slags.

8.SAFE - no free silica, is chemically inert and non toxic, heavy metal free in most cases.

9.Inert - can use it around water

10.Mohs hardness of 6.0 - similar to slags.

11.Superior rust-back performance when compared with mineral/slag abrasives.

12.Many tests confirm less dust when blasting with glass vs mineral slags - up to 31% less dust generated.

13.Contains no beryllium like mineral slags do.

14.Uniform density

15.Dust is translucent! No visual barrier to the blasting operator and does not leave black "Dust" All over.

16.A great alternative to coal slag. Contains no beryllium and will not leave black dust all over.

17.Great for thick, softer coatings because it is a lighter weight abrasive. It does not "Bounce" Back off the surface. It cuts it like a knife.

18.Great for concrete and leaves no residue, discoloration, odor, imbedding, or ferrous impingement.

19.Excellent additive for seal coating operations!

20.Excellent replacement for soda blasting due to its lower cost and it will not leave a ph imbalance on the substrate (which often requires a ph wash solution so that the paint will adhere). Glass will also cut through rust, and soda blast will not.

21.Excellent replacement for corn cob blasting log homes as it will not embed into the wood, and thus you do not have to hand sand after blasting. (this can equate to an 80% time savings over corn cob.)

22.100% recycled post-consumer bottle glass it is a green abrasive! 100% recycled glass.